18 KiB

FilaMan Wiki - English

Table of Contents

- Overview

- Installation

- Hardware Requirements

- Initial Setup

- Configuration

- Usage

- NFC Tags

- Bambu Lab Integration

- Spoolman Integration

- Octoprint Integration

- Manufacturer Tags

- Troubleshooting

- Support

Overview

FilaMan is a comprehensive filament management system for 3D printers based on ESP32 hardware. It provides weight measurement, NFC tag management, and seamless integration with Spoolman and Bambu Lab 3D printers.

Key Features

- Precise weight measurement with HX711 load cell amplifier

- NFC tag reading and writing for filament identification

- OLED display for status information

- WiFi connectivity with easy configuration

- Web-based user interface with real-time updates

- Spoolman integration for inventory management

- Bambu Lab AMS control via MQTT

- OpenSpool NFC format compatibility

- Manufacturer tag support for automatic setup

System Requirements

- ESP32 Development Board

- Spoolman Instance (required for full functionality)

- WiFi Network

- Web Browser (Chrome/Firefox/Safari)

Installation

Easy Installation (Recommended)

-

Open the FilaMan Web Installer

- Use a Chrome-based browser

-

Prepare ESP32

- Connect ESP32 via USB to your computer

- Click "Connect"

-

Select Port

- Choose the appropriate USB port

- Confirm selection

-

Start Installation

- Click "Install FilaMan"

- Wait for installation to complete

Manual Compilation

For advanced users with PlatformIO:

git clone https://github.com/ManuelW77/Filaman.git

cd FilaMan/esp32

pio lib install

pio run --target upload

Hardware Requirements

Required Components

| Component | Description | Amazon Link (Affiliate) |

|---|---|---|

| ESP32 Development Board | Any ESP32 variant | Amazon |

| HX711 + Load Cell | 5kg Load Cell Amplifier | Amazon |

| OLED Display | 0.96" I2C 128x64 SSD1306 | Amazon |

| PN532 NFC Module | V3 RFID Module | Amazon |

| NFC Tags | NTAG213/NTAG215 | Amazon |

| TTP223 Touch Sensor | Optional for tare function | Amazon |

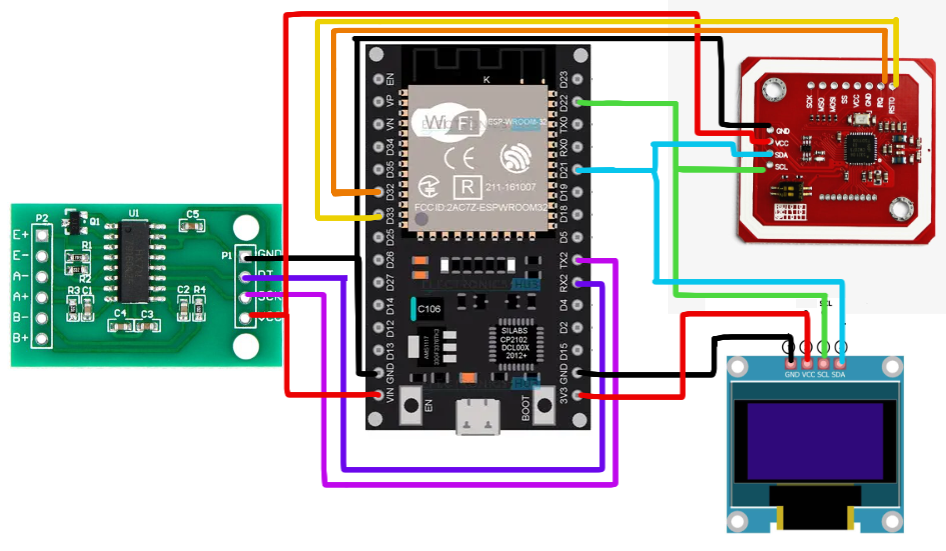

Pin Configuration

| Component | ESP32 Pin | Function |

|---|---|---|

| HX711 DOUT | 16 | Load cell data output |

| HX711 SCK | 17 | Load cell clock |

| OLED SDA | 21 | I2C data |

| OLED SCL | 22 | I2C clock |

| PN532 IRQ | 32 | Interrupt |

| PN532 RESET | 33 | Reset |

| PN532 SDA | 21 | I2C data (shared) |

| PN532 SCL | 22 | I2C clock (shared) |

| TTP223 I/O | 25 | Touch sensor (optional) |

Important Notes

- PN532 DIP switches must be set to I2C mode

- 3V pin from ESP32 for touch sensor

- Load cell wiring: E+ (red), E- (black), A- (white), A+ (green)

Initial Setup

After Installation

-

ESP32 Restart

- System automatically creates a WiFi hotspot "FilaMan"

-

WiFi Configuration

- Connect to the "FilaMan" network

- Open browser (automatic portal or http://192.168.4.1)

- Configure your WiFi credentials

-

First Access

- After successful WiFi connection, access system at http://filaman.local

- Alternative: Use IP address assigned by router

Spoolman Preparation

Important Note: Spoolman must run in debug mode:

# Uncomment in Spoolman's .env file:

SPOOLMAN_DEBUG_MODE=TRUE

This is required as Spoolman doesn't support CORS domain configuration yet.

Configuration

Scale Calibration

-

Start Calibration

- Go to "Scale" page

- Prepare a 500g reference weight (e.g., water glass)

-

Calibration Steps

- Follow instructions on display

- Place weight when prompted

- Wait for calibration to complete

-

Validation

- Test accuracy with known weights

- Use "Tare Scale" for zero adjustment if needed

Spoolman Connection

-

Enter Spoolman URL

- Go to "Spoolman/Bambu" page

- Enter complete URL of your Spoolman instance

- Format:

http://spoolman-server:7912

-

Test Connection

- System automatically checks connection

- Successful connection shown by green status

Bambu Lab Printer (Optional)

-

Printer Settings

- Open settings menu on your Bambu printer

- Note the following data:

- Printer IP address

- Access Code

- Serial Number

-

FilaMan Configuration

- Enter printer data on "Spoolman/Bambu" page

- Enable "Auto Send to Bambu" for automatic AMS assignment

-

Auto-Send Timeout

- Configure waiting time for automatic spool detection

- Recommended value: 10-30 seconds

Usage

Basic Operation

-

Weigh Filament

- Place spool on scale

- Weight automatically displayed on screen and web interface

-

Scan NFC Tag

- Hold tag near PN532 module

- Recognized tags display spool information

- Weight automatically updated in Spoolman

-

Status Monitoring

- OLED Display shows current weight and connection status

- Web Interface provides detailed information and control

Web Interface Navigation

- Home: Main functions and current status

- Scale: Scale calibration and settings

- Spoolman/Bambu: System configuration

- Statistics: Usage statistics (if enabled)

NFC Tags

Supported Tag Types

- NTAG213: 144 bytes (basic functions)

- NTAG215: 504 bytes (recommended)

- NTAG216: 888 bytes (extended functions)

Writing Tags

-

Prepare Spool in Spoolman

- Create new spool in Spoolman

- Ensure all required data is entered

-

Start Tag Writing

- Select spool from list

- Click "Write Tag"

- Display shows "Waiting for Tag"

-

Place Tag

- Position NFC tag on PN532 module

- Wait for confirmation

-

Success Message

- Successful writing shows checkmark

- Tag is now linked to Spoolman spool

Reading Tags

-

Scan Tag

- Place the spool with NFC tag on the scale over the NFC reader

- If reading fails: Reposition spool slightly (not completely at the edge)

- Spool information automatically loaded

-

Automatic Updates

- Current weight transferred to Spoolman

- Spool automatically selected in web interface

Bambu Lab Integration

AMS (Automatic Material System)

-

Display AMS Status

- Web interface shows current state of all AMS slots

- Loaded slots display filament information

-

Manual Filament Assignment

- Select spool from Spoolman list

- Click corresponding AMS slot icon

- Filament assigned to slot

-

Automatic Assignment

- After weighing with "Auto Send to Bambu" enabled

- System waits for new spools in AMS

- Calibrated filaments automatically assigned

Bambu Studio Integration

-

Sync Filament Profiles

- Calibrate filaments in Bambu Studio

- Use Device → AMS → Pencil icon → Select

-

Save Setting IDs

- FilaMan automatically detects available setting IDs

- Click "Save Settings to Spoolman"

- Profiles used for future prints

Restore Connection

- For connection issues, click red dot in menu bar

- System automatically establishes new connection

Spoolman Integration

Automatic Functions

-

Spool Synchronization

- Automatic transfer of weight changes

- Real-time updates of spool data

-

Extra Fields

- FilaMan automatically creates required custom fields

- NFC tag UID stored as reference

-

Filtering

- "Show only spools without NFC tag" for easy tag assignment

- Categorization by manufacturers and material types

Spoolman Octoprint Plugin

For Octoprint users, automatic spool assignment is available:

-

Install Plugin

https://github.com/ManuelW77/OctoPrint-Spoolman-Filaman/archive/refs/heads/master.zip -

Configure FilaMan

- Enable "Send to Octo-Plugin"

- Enter Octoprint URL and API key

-

Automatic Assignment

- After weighing, spool automatically activated in Octoprint

- Currently supports only Tool0 (first nozzle)

Manufacturer Tags

Overview

Manufacturer tags allow filament producers to provide pre-configured NFC tags that automatically create all necessary entries in Spoolman.

Getting Started with Manufacturer Tags

-

Scan Tag

- Place spool with manufacturer tag on the scale over the NFC reader

- If reading fails: Reposition spool slightly (not completely at the edge)

- System automatically recognizes manufacturer format

-

Automatic Creation

- Brand created in Spoolman (if not present)

- Filament type created with all specifications

- Spool automatically registered

-

Future Scans

- After initial setup, tags use fast-path system

- Immediate weight measurement without re-setup

Supported Manufacturers

- RecyclingFabrik: First official partner

- More manufacturers coming soon

Benefits

- ✅ Zero manual setup

- ✅ Perfect data accuracy

- ✅ Instant integration

- ✅ Future-proof

Troubleshooting

Common Issues

WiFi Connection

Issue: Cannot connect to FilaMan hotspot

- Solution: Ensure ESP32 is started

- Alternative: Manually navigate to http://192.168.4.1

Issue: Web interface not accessible

- Solution: Check IP address in router

- Alternative: Use http://filaman.local

Scale

Issue: Inaccurate weight measurements

- Solution: Repeat calibration

- Tip: Use "Tare Scale" for zero adjustment

Issue: Load cell not responding

- Solution: Check wiring (E+, E-, A+, A-)

- Tip: Test with multimeter

NFC Tags

Issue: Tag not recognized

- Solution: Check PN532 DIP switches (I2C mode)

- Tip: Reposition spool slightly on scale (not completely at the edge)

Issue: Cannot write tag

- Solution: Use NTAG215 for better compatibility

- Tip: Ensure tag is not write-protected

Spoolman

Issue: Connection to Spoolman fails

- Solution: Enable SPOOLMAN_DEBUG_MODE=TRUE

- Tip: Check URL formatting

Issue: Spools not displayed

- Solution: Ensure Spoolman is running

- Tip: Check network firewall settings

Bambu Lab

Issue: Printer won't connect

- Solution: Check access code and IP address

- Tip: Ensure printer is in LAN mode

Issue: AMS status not displayed

- Solution: Check MQTT connection

- Note: Bambu may close API at any time

Debug Information

If you have problems, you can use these steps for diagnosis:

Serial Monitor (for developers)

- Connect the ESP32 via USB to your computer

- Open a serial monitor (e.g., Arduino IDE) with 115200 baud

- You will see detailed log messages from the system

Browser Console

- Open the FilaMan web interface

- Press F12 to open developer tools

- Check the console for error messages

Maintenance and Updates

Firmware Update

- Via Web Interface: Access

http://filaman.local/upgrade.html - Select firmware file (.bin format)

- Upload - System restarts automatically

- Configuration preserved - Settings remain intact

System Reset

For persistent issues:

- Disconnect ESP32 from power

- Wait 10 seconds

- Reconnect

- Wait 30 seconds for complete startup

Support and Information

Manufacturer: Your Company Name Maintainer: Manuel W.

Scale Technology

Weight Stabilization

The system uses multiple filters for precise measurements:

// Moving Average Filter with 8 values

#define MOVING_AVERAGE_SIZE 8

// Low-Pass Filter for smoothing

#define LOW_PASS_ALPHA 0.3f

// Thresholds for updates

#define DISPLAY_THRESHOLD 0.3f // Display update

#define API_THRESHOLD 1.5f // API actions

Calibration Algorithm

- System Pause: All tasks are temporarily paused

- Zero Setting: Tare scale without weight

- Reference Measurement: 500g weight for 10 measurements

- Calculation:

newValue = rawValue / SCALE_LEVEL_WEIGHT - NVS Storage: Permanent value with verification

- Filter Reset: New baseline for stabilization

Auto-Tare Logic

// Conditions for Auto-Tare

if (autoTare && (weight > 2 && weight < 7) || weight < -2) {

scale_tare_counter++;

if (scale_tare_counter >= 5) {

// Automatic zero setting

scale.tare();

resetWeightFilter();

}

}

NFC Technology

PN532 Communication

- Interface: I2C at 400kHz

- IRQ Pin: Interrupt-based tag detection

- Reset Handling: Automatic recovery from communication errors

- DIP Switches: Must be set to I2C mode (00)

NDEF Implementation

// FilaMan Spoolman Format (with sm_id)

{

"sm_id": "123",

"color": "#FF5733",

"type": "PLA",

"brand": "Example Brand"

}

Manufacturer Tag Schema

Compact JSON format for storage efficiency:

{

"b": "RecyclingFabrik", // brand

"an": "FX1_PLA-S175-1000-RED", // article number

"t": "PLA", // type

"c": "FF0000", // color (hex without #)

"cn": "Red", // color name

"et": "210", // extruder temp

"bt": "60", // bed temp

"di": "1.75", // diameter

"de": "1.24", // density

"sw": "240", // spool weight

"u": "https://www.yoururl.com/search?q=" // URL used vor Brand Link and Filament Link

}

Display System

OLED Architecture (SSD1306)

- Resolution: 128x64 pixels monochrome

- Areas:

- Status bar: 0-16 pixels (version, icons)

- Main area: 17-64 pixels (weight, messages)

- Update Interval: 1 second for status line

Icon System

Bitmap icons for various states:

// Status Icons (16x16 pixels)

- icon_success: Checkmark for successful operations

- icon_failed: X for errors

- icon_transfer: Arrow for data transmission

- icon_loading: Loading circle for ongoing operations

// Connection Icons with strikethrough indicator

- wifi_on/wifi_off: WLAN status

- bambu_on: Bambu Lab connection

- spoolman_on: Spoolman API status

API Integration

Spoolman REST API

FilaMan interacts with the following endpoints:

GET /api/v1/spool/ # List spools

POST /api/v1/spool/ # Create new spool

PUT /api/v1/spool/{id}/ # Update spool

GET /api/v1/vendor/ # List vendors

POST /api/v1/vendor/ # Create new vendor

GET /api/v1/filament/ # List filaments

POST /api/v1/filament/ # Create new filament

Request Handling

// Sequential API processing

enum spoolmanApiStateType {

API_IDLE = 0,

API_PROCESSING = 1,

API_ERROR = 2

};

Prevents simultaneous API calls and deadlocks.

Weight Update Logic

// Conditions for Spoolman update

if (activeSpoolId != "" &&

weigthCouterToApi > 3 && // 3+ stable measurements

weightSend == 0 && // Not yet sent

weight > 5 && // Minimum weight 5g

spoolmanApiState == API_IDLE) {

updateSpoolWeight(activeSpoolId, weight);

}

Bambu Lab MQTT

Connection Parameters

// SSL/TLS Configuration

#define BAMBU_PORT 8883

#define BAMBU_USERNAME "bblp"

// Topic Structure

String topic = "device/" + bambu_serial + "/report";

String request_topic = "device/" + bambu_serial + "/request";

AMS Data Structure

struct AMSData {

String tray_id;

String tray_type;

String tray_color;

String tray_material;

String setting_id;

String tray_info_idx;

bool has_spool;

};

Auto-Send Mechanism

// After tag recognition

if (bambuCredentials.autosend_enable) {

autoSetToBambuSpoolId = activeSpoolId.toInt();

// Countdown starts automatically

// Waits for new spool in AMS

}

WebSocket Communication

Message Types

// Client → Server

{

"type": "writeNfcTag",

"tagType": "spool",

"payload": { /* JSON data */ }

}

{

"type": "scale",

"payload": "tare|calibrate|setAutoTare",

"enabled": true

}

// Server → Client

{

"type": "heartbeat",

"freeHeap": 245,

"bambu_connected": true,

"spoolman_connected": true

}

{

"type": "amsData",

"data": [ /* AMS array */ ]

}

Connection Management

- Auto-Reconnect: Client-side reconnection

- Heartbeat: Every 30 seconds for connection monitoring

- Cleanup: Automatic removal of dead connections

Watchdog and Error Handling

System Watchdog

// WDT Configuration

esp_task_wdt_init(10, true); // 10s timeout, panic on overflow

esp_task_wdt_add(NULL); // Add current task

Error Recovery

- NFC Reset: Automatic PN532 restart on communication errors

- MQTT Reconnect: Bambu Lab connection automatically restored

- WiFi Monitoring: Connection check every 60 seconds

Support

Community

- Discord Server: https://discord.gg/my7Gvaxj2v

- GitHub Issues: Filaman Repository

- YouTube Channel: German explanation video

Documentation

- Official Website: www.filaman.app

- GitHub Wiki: Detailed documentation

- Hardware Reference: ESP32 pinout diagrams in

/img/

Support Development

If you'd like to support the project:

License

This project is released under the MIT License. See LICENSE for details.

Last Updated: August 2025

Version: 2.0

Maintainer: Manuel W.